OptiCol™ Human Collagen Type III (1 mg/ml), 10 mg

Description

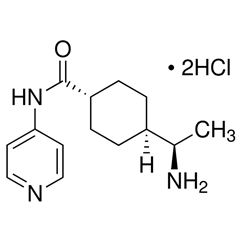

OptiCol™ Human Collagen Type III is initially produced as procollagen, a protein consisting of three pro-α1(III) chains that form the triple-stranded, rope-like molecule. After being synthesized, the procollagen molecule is modified by the cell.

Applications

3D Gels | Tissue engineering research | Wound healing constructs | Coatings | Solid free-form fabrications | Electrospinning | in-vitro research | Nerve Repair, Hemostats, Sealants, Coils, Sponges, Spheres/Beads, Ligaments, Strings, Tubes/Cylinders, Films| Product Details | |

|---|---|

| Source | Human Placenta |

| Gelation Time | <60 mins |

| Fibril Formation | >0.35 abs. units |

| Purity | >99.9% |

| pH | approx 2 |

| Telo vs. Atelo | Atelo-collagen |

| Endotoxin Level | ≤10.0 EU/ml as measured by kinetic LAL |

| Sterility | No growth |

| Concentration | ~ 1 mg/ml |

| SDS-PAGE |

Characteristic; approximately 85% Type III and 15% Type I |

| Adventitious Agents | The human source material has been tested and found negative for hepatitis B virus, hepatitis C virus, and for human immunodeficiency virus-1 (HIV-1) |

| Storage and Stability | 4°C |

Protocols

Coating Procedure

Note: Use these recommendations as guidelines to determine the optimal coating conditions for your culture system.

1. Remove required quantity of collagen from the bottle and dispense into a dilution vessel.

2. Dilute Type III collagen solution with a 0.01 M HCl solution water to ~50 to 100 μg/ml (~1:10).

3. Swirl contents gently until material is completely mixed.

4. Add appropriate amount of diluted Type III Collagen to the culture surface ensuring that the entire surface is coated.

5. Incubate at room temperature, covered for 1 - 2 hours.

6. After incubation, aspirate any remaining material.

7. Rinse coated surfaces carefully with sterile medium or PBS, avoid scratching surfaces.

8. Coated surfaces are ready for use. They may also be stored at 2 - 10°C damp or air dried if sterility is maintained.